Your bi-weekly sync on the pulse of the simulation industry

Industry News

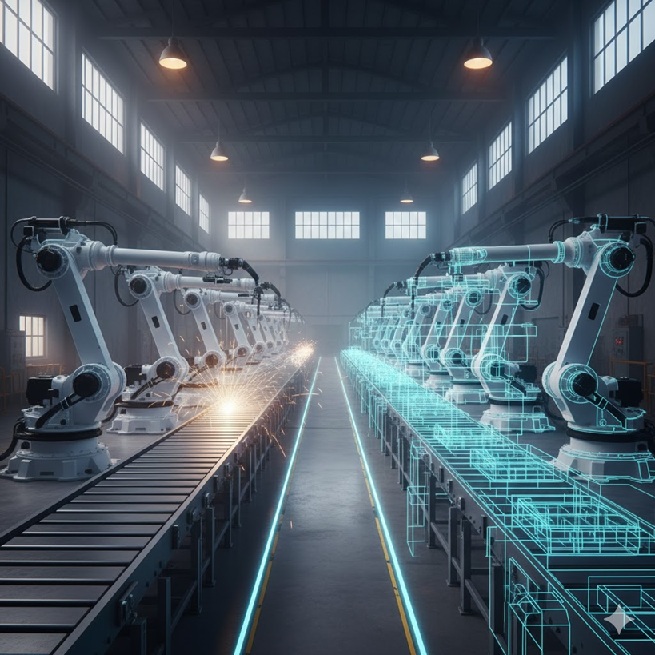

Siemens unveiled its Digital Twin Composer, at CES 2026, a tool designed to build the industrial metaverse. By integrating NVIDIA Omniverse, the software allows companies to create photorealistic, physics-based digital twins of entire factories.

PepsiCo is already piloting the technology to “co-design” facilities with AI, reporting an increase in throughput and reduced capital expenditure by identifying potential issues before construction begins. This isn’t just a 3D model; it’s a living virtual environment where robots are trained and production lines are optimized in real-time.

Beyond simple visualization, the Composer acts as a unified data thread, pulling in live sensor data and PLC code to allow engineers to “rewind” and “fast-forward” through production cycles to stress-test scenarios like weather-driven supply chain shifts or sudden SKU changes. This shift toward generative simulation means the digital twin no longer just mirrors reality—it actively proposes the most efficient path forward, turning the factory floor into a self-optimizing ecosystem.

Product News

Features

Accelerated Frequency Analysis

Full-Scale Model Support

Automated Design Optimization

Features

Virtual Passenger Comfort

IP-Protected Co-Simulation

Accelerated Virtual Validation

Features

Live Result Plotting

Advanced Experiment View

Modernized Code Editor

Features

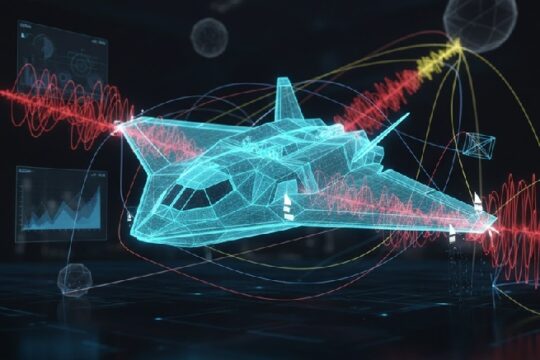

- Physically Accurate RF Validation

- Operational Parallel Twins

- Cloud-Native Scaling

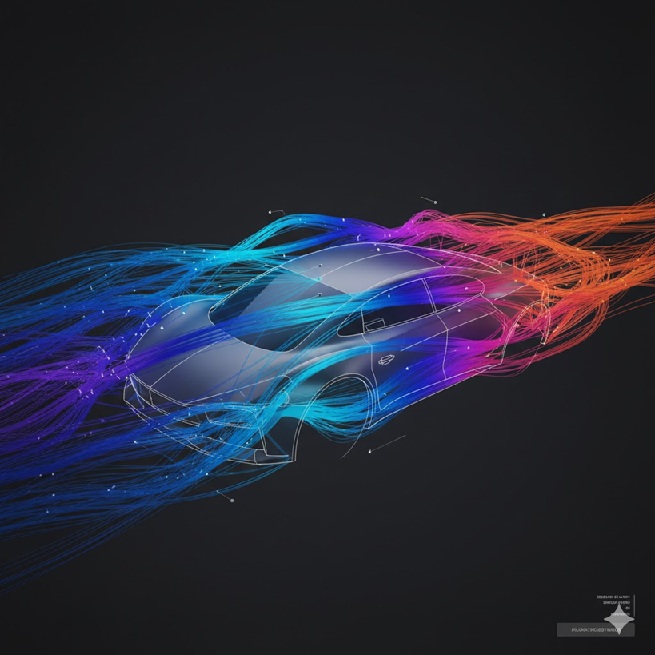

Dassault Systèmes is enhancing accessibility for Computational Fluid Dynamics (CFD). Traditionally a domain for specialists, the new Fluid Dynamics Engineer role on the 3DEXPERIENCE platform now uses advanced user experience (UX) design to make complex simulations intuitive for a wider range of engineers. With features like automated gap filling and AI-guided assistants, 3DS is integrating simulation earlier into the design process, accelerating insights and streamlining development without compromising scientific accuracy.

Synopsys recently demonstrated a new simulation framework at Microsoft Ignite that slashes manufacturing simulation times from hours to just minutes. By leveraging NVIDIA Omniverse and Microsoft Azure, the system allows companies like Krones to optimize complex assembly lines—such as high-speed bottle filling—in near real-time. This leap in speed means engineers can test “what-if” scenarios instantly on the factory floor, reducing waste and improving production agility without stopping the physical machines.

A recent Engineering.com article highlights that for AI to truly transform the physical world, companies must first master “Digital Engineering.” By moving away from silos and toward an integrated “digital thread,” engineers can now train AI models on high-fidelity simulation data. This convergence allows for more than just faster math; it enables “Agentic AI” to work alongside humans as a co-pilot, refining workflows and predicting system behaviors with a level of accuracy that was previously impossible without physical prototypes.

AVL RACETECH has partnered with MissionH24 to develop hydrogen-based, zero-emission powertrains for endurance racing. Utilizing its AVL VSM™ RACE simulation software, AVL will provide virtual vehicle development to optimize the energy management and performance of the H24EVO hydrogen-electric prototype. The collaboration aims to establish a dedicated hydrogen category at the 24 Hours of Le Mans, demonstrating the competitiveness of decarbonized technology under extreme racing conditions.

Industry Events

The GT Technical Conference (GTTC) in Pune showcases the latest advancements in systems simulation, focusing on electrification, thermal management, and digital twins. The event features technical sessions, expert presentations, and real-world case studies designed to help engineers accelerate product development and solve complex design challenges.

📅 February 9-10, 2026 🕚 7 :45 AM – 5 PM IST

📍Hyatt Regency Pune & Residences

Weikfield IT Citi Info Park, Nagar Rd, Sakore Nagar, Viman Nagar, Pune, Maharashtra 411014 India

This MathWorks webinar demonstrates how to combine system simulation with machine learning to develop advanced algorithms for fault detection and asset health monitoring in the energy sector. Attendees will learn how to generate synthetic data, train predictive maintenance models, and use AI-based virtual sensors to improve the reliability of critical assets like power converters, motors, and grid systems.

📅 February 12, 2026

🕚 12:00 PM PST

This webinar is designed for educators and students to simplify complex CFD concepts using intuitive, real-world examples like pipe-flow losses. Attendees will learn practical strategies for

- Visualizing flow behavior

- Overcoming meshing challenges for complex geometries

- Comparing simulation results with experimental data

It serves as a comprehensive guide for connecting CFD principles across various engineering disciplines, including aerospace, mechanical, and biomedical engineering.

📅 February 17, 2026

🕘 11 AM EST

This webinar explores how digital engineering and simulation are accelerating the development of autonomous eVTOL vehicles and advanced air mobility platforms. Experts will discuss integrating high-fidelity synthetic sensor data and model-based workflows to validate safety and streamline the certification process for next-generation aerospace systems.

📅 February 19, 2026

🕘 03:00 PM EST/ Noon PST

In FOCUS

Company in Focus

Who they are

Founded in the late nineties and headquartered in Guangzhou, ZWSOFT has evolved from a 2D CAD specialist into a global powerhouse for All-in-One CAx (CAD/CAM/CAE) solutions. With a massive international user base spanning dozens of countries, the company is defined by its significant investment in R&D and its ownership of the Overdrive 3D geometric modeling kernel, which gives them full control over their software’s “brain.”

Solutions & Technology

The ZWSOFT ecosystem is built on a unified “product matrix” designed to eliminate the need for switching between different software brands:

ZWCAD: A high-performance 2D CAD platform featuring AI-powered automation (like Smart Match and Similar Search) and a new self-developed parametric constraint engine.

ZW3D: A hybrid modeling tool that combines solid and surface design with manufacturing. The latest version introduces native CFD (fluid dynamics) through their acquisition of CHAM (PHOENICS), allowing for real-time thermal and flow analysis.

ZWSim: A dedicated CAE suite for Electromagnetic, Structural, and Fluid simulation, enabling engineers to test digital twins against real-world physics.

Applications:

ZWSOFT targets industries where high-precision engineering meets high-volume production:

Mechanical & Manufacturing: Focused on “efficiency elevation,” using tools like the Hole Generator and Screw Connection wizard to automate the most tedious assembly tasks.

AEC (Architecture, Engineering, Construction): Providing specialized BIM and drafting tools for large-scale infrastructure and smart city development.

Energy & Power: Following the acquisition of BochaoSoft, they offer specialized 3D design solutions for electrical power grids and substations.

Did you know?

ZWSOFT is spearheading the “One Window” Revolution, a movement to end the slow and risky process of “software hopping” by unifying design, simulation, and manufacturing into a single interface that can slash modeling time for complex parts considerably. This deep technical integration is powered by their acquisition of CHAM, founded by the “Father of CFD,” Brian Spalding, and features unique innovations like Smart Voice, which allows engineers to embed spoken instructions directly into their blueprints to eliminate manual communication errors.

Solution Focus

ZWSOFT aims to redefine the product lifecycle by providing professional-grade tools with streamlined workflows and unmatched accessibility.

Unified Workflow: Designing, simulating, and manufacturing without ever needing to export a file.

High Performance: Handling massive assemblies smoothly with advanced display engines.

Sustainability: Reducing physical prototyping costs through high-fidelity digital twin validation.

Technology Focus

Designing the tiny sensors in our smartphones and cars—like the gyroscopes that rotate your screen or the micro speakers in your earbuds—is incredibly difficult because they involve “multiphysics.” This means the electricity, the physical movement, and the surrounding air all push and pull on each other at the same time. Traditionally, simulating these interactions was so slow that engineers had to take “math shortcuts,” which weren’t always accurate.

Real Physics, Faster: Quanscient Allsolve uses the cloud to solve these complex physics equations significantly faster than traditional software, turning hours of waiting into minutes.

Better Sound & Performance: By simulating everything together, engineers achieved a substantial increase in microspeaker volume while keeping the sound crystal clear.

Less Guesswork: Instead of building and breaking expensive physical prototypes, designers can now test numerous virtual versions to find the perfect design.

A Foundation for Innovation: This breakthrough is a game-changer for the next generation of wearable tech and autonomous sensors, where every millimeter of space and milliwatt of power counts. By capturing the true interaction of forces at a microscopic scale, companies can move from a concept to a finished product in a fraction of the usual time.