Industry News

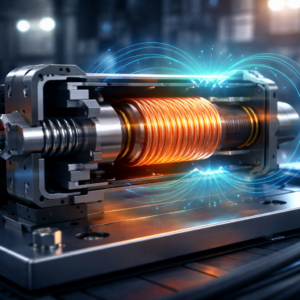

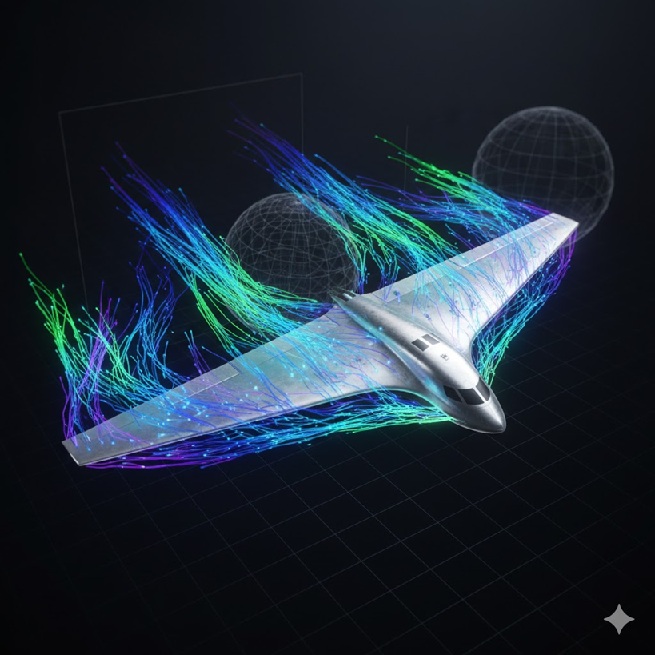

In today’s engineering landscape, the race for efficiency is won in the digital realm. A recent Cadence feature highlights how Fidelity CFD software is transforming turbomachinery design—from turbochargers to massive industrial compressors.

The post showcases three breakthrough case studies:

- Toyota Motorsports: Improved turbocharger compressor efficiency while staying within structural limits using multi-disciplinary optimization.

- ENTECHMACH: Achieved boost in polytropic efficiency for a three-stage air compressor, reducing power consumption.

- Full Engine Simulation: Successfully modeled a gas turbine’s entire flow path in one go, capturing complex unsteady phenomena that traditional component-by-component testing often misses.

By leveraging high-fidelity simulations, engineers are no longer just guessing; they are “making every RPM count,” ensuring maximum performance, lower emissions, and faster time-to-market.

Product News

At the recent SC25 conference, the conversation shifted from raw hardware power to the era of AI-First Digital Engineering. Rescale used the global stage to demonstrate that traditional High-Performance Computing (HPC) is no longer a standalone tool, but the foundation for a new “AI Physics” ecosystem. Rescale showcased how leaders like General Motors Motorsports are already using automated, agent-driven workflows to compress development cycles proving that the future of simulation is as much about artificial intelligence as it is about physics.

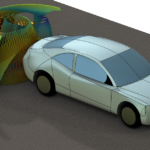

We have all heard that modern cars are basically “computers on wheels,” but Synopsys demonstrated how they are actually engineered. At CES 2026 (Consumer Electronics Show), the big news wasn’t a new vehicle, but the digital workshop used to build them.

Synopsys is pushing a “Virtual-First” approach that lets car makers simulate every single electronic chip and software line in a digital twin long before a physical prototype is ever built.

Convergent Science aims to accelerate the future of fluid dynamics by integrating NVIDIA GPU support into its flagship CONVERGE CFD software. This update specifically supercharges the software’s signature autonomous meshing technology, allowing the simulation grid to be generated and adapted in real-time with unprecedented speed. By shifting these heavy computational loads from CPUs to GPUs, engineers can now achieve high-fidelity results for complex systems—like industrial engines and mixing tanks—in considerably lesser time, turning days of waiting into just hours of work.

Industry Events

This webinar explores how simulation helps students visualize complex concepts like stress and strain in real time. It provides practical resources for university programs to bridge the gap between theoretical textbooks and hands-on engineering using Ansys Discovery and Mechanical.

📅 January 26, 2026 🕚 11:00 AM EST/21:30 IST

This webinar shows how to link system design with real-world mission goals to ensure a project succeeds in the field. It demonstrates how to use MATLAB and Simulink to run “what-if” scenarios, helping teams pick the best architecture before any hardware is built.

📅 January 28, 2026

🕚 19:30 IST

This webinar explores how machine learning and modern testing methods can make COMSOL simulations faster and more accurate. It features real-world customer use cases to demonstrate how to turn complex models into high-speed digital twins for real-time prediction.

📅 Thursday, January 29, 2026

🕘 08:00 AM CST / 19:30 IST

This in-person event at The Orchid Hotel Mumbai offers a deep dive into multiphysics modeling, featuring a mix of technical demos and industry-led keynote talks. Attendees can explore the latest updates in COMSOL Multiphysics version 6.4, including specialized sessions on electromagnetics, fluid flow, and structural mechanics, while networking with experts.

📅January 30, 2026

🕘 9:30 am IST

📍The Orchid Hotel Mumbai Vile Parle, Mumbai, India 400099

In FOCUS

Company in Focus

Who they are

oorja is a battery intelligence company that helps manufacturers predict how batteries will behave before they are ever built. By moving away from slow, expensive physical testing, they enable engineers to “shift-left”—identifying potential safety and performance issues in the design phase rather than in the lab.

The leadership team, including Dr. Vineet Dravid, Dr. Prashant Kumar Srivastava, and Prajakta Vaidya-Sabins, brings over 40 years of experience from the highest levels of the engineering software industry. This deep domain knowledge allows them to build tools that speak the language of professional engineers while leveraging modern computation.

Solutions & Technology

oorja’s core advantage is its Hybrid Modeling approach. While traditional tools are often too slow or require massive amounts of data, oorja blends physics-based rules with machine learning to get results that are both fast and accurate.

oorja Battery Suite: A cloud platform for designing safer battery packs, optimizing cooling, and predicting how batteries will age over time.

oorja Battery 360™: A dashboard for real-world monitoring, helping operators track the health and remaining life of batteries already on the road.

Applications:

The company’s technology is designed for the most demanding energy sectors:

Electric Vehicles (EV): From 2-wheelers to heavy-duty trucks, optimizing range and safety.

Energy Storage Systems (ESS): Ensuring the stability of large-scale grid storage.

Cell Manufacturing: Helping cell makers qualify new chemistries and designs faster.

Did you know?

oorja was named a winner of the NASSCOM Emerge 50 Awards (2024), recognizing them as one of India’s most innovative deep-tech startups. Despite being a lean team, they house 7 PhDs who have collectively optimized over 200 unique battery designs using technology that can predict a battery’s life cycle with data from just 10 charging cycles.

Solution Focus

oorja aims to redefine battery engineering by solving complex problems with “expert-grade simplicity” and unmatched speed.

Safety: Predicting and preventing “thermal runaway” (battery fires).

Longevity: Accurately estimating battery warranties and degradation.

Speed: Providing insights up to 8x faster than traditional simulation tools.

Technology Focus

Modern sustainable architecture requires a shift from “guess-and-check” methods to high-fidelity environmental simulation. By adopting cloud-native Computational Fluid Dynamics (CFD), engineering teams—such as those at DLR Group—can now embed performance insights at the moment decisions are made, rather than as an afterthought. This approach allows for the rapid testing of “what-if” scenarios, such as natural ventilation and solar gain, by running multiple simulations simultaneously in the cloud without the need for expensive local hardware.

This data-driven workflow is particularly valuable for complex projects in challenging climates, where engineers must validate that innovative HVAC solutions won’t lead to condensation or occupant discomfort. Beyond the structure itself, the technology enables automated pedestrian wind comfort analysis by importing localized geographical data. This identifies potential safety risks in outdoor spaces long before construction begins, ensuring that sustainable campuses remain functional and comfortable year-round.

💡 Strategic Insight: De-Risking Early

The most expensive design changes are those made after construction begins. Using early-stage simulation allows teams to “fail fast” on paper. By testing high-risk ideas—like experimental cooling methods—in a virtual environment, you can confidently discard impractical concepts before they impact your structural budget or timeline.