Optimization of a high-efficiency oil cooler for powertrain systems

This report details the design and optimization process for a cross-flow oil cooler developed by ToffeeX for Nissan. The primary objective of this activity was to maximize heat transfer between coolant and engine oil within defined constraints, including maximum allowable pressure drops and printability requirements for additive manufacturing. The project employed ToffeeX’s thermo-fluid topology optimization design techniques to explore innovative solutions.

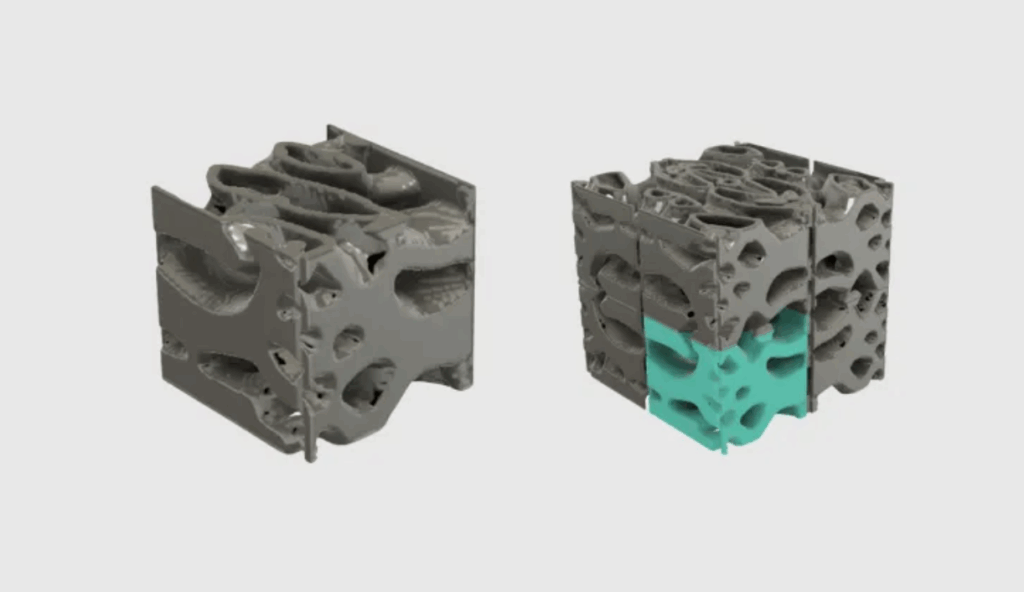

The final design proved to be approximately 15 times more effective in terms of heat transfer-to-pressure drop ratio compared to both the reference gyroid and plated heat exchanger designs. Moreover, both printability and minimum wall thickness constraints were achieved, demonstrating ToffeeX’s design for manufacturing functionalities. A 3D printed plastic prototype was manufactured and shipped to Nissan as a deliverable of this project.