Your bi-weekly sync on the pulse of the simulation industry

Industry News

For many years, the maritime industry has depended on engineering to improve efficiency, but today, some of the most innovative ideas are inspired by marine life. One such example is Bluefins’ whale-inspired energy-recovery propulsion concept, which draws on the natural motion of whale fins to improve how ships move through water.

Instead of relying solely on conventional propellers, the system introduces a hydrofoil positioned at the stern of a vessel. As the ship travels through waves, the foil moves in response to water motion, generating additional thrust from energy that would otherwise dissipate. In effect, it converts wave-induced motion into useful propulsive force, helping reduce fuel consumption and overall operating costs.

A key part of the development process has been the use of advanced computational fluid dynamics tools, including Cadence’s Fidelity CFD platform, specifically Fidelity Fine/Marine for flow simulation and Fidelity Pointwise for high-quality mesh generation. These tools were applied to simulate complex free-surface flows, hull–foil interactions, and vessel motions in realistic sea conditions. By running detailed virtual analyses, engineers could study how the hydrofoil behaves under varying wave patterns and operating scenarios without relying solely on physical prototypes.

The concept reflects a broader shift in marine innovation: combining bio-inspired design with high-fidelity simulation. As shipping faces increasing pressure to operate more efficiently and sustainably, such hybrid thinking may become an important part of the industry’s evolving toolkit.

Product News

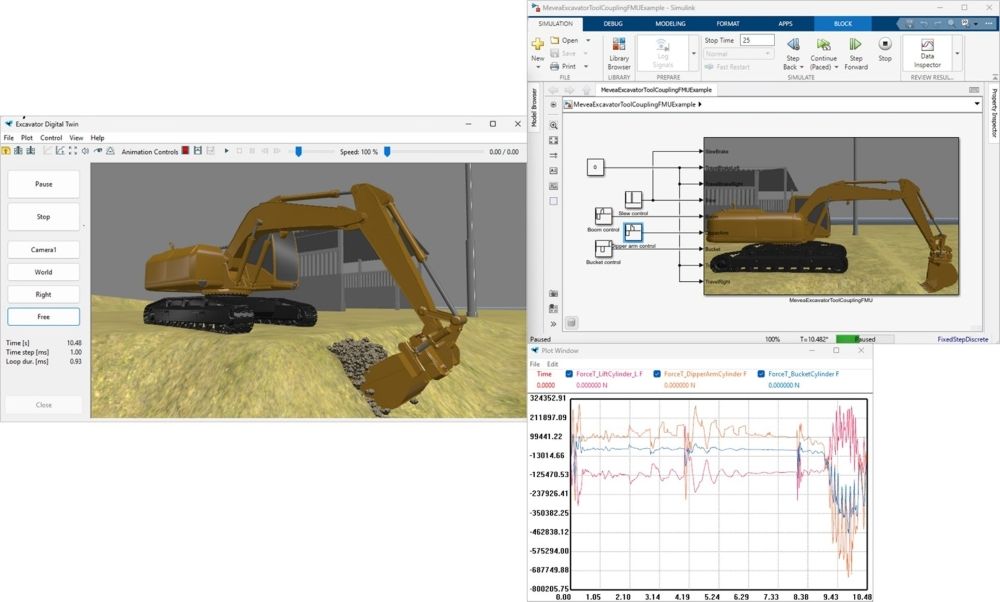

Features:

- Real-Time Multibody Simulation

- Soil/Terrain Modeling

- HIL/SIL Co-Simulation Integration

Features:

- CAD-Ready Outputs

- Rapid Variant Exploration

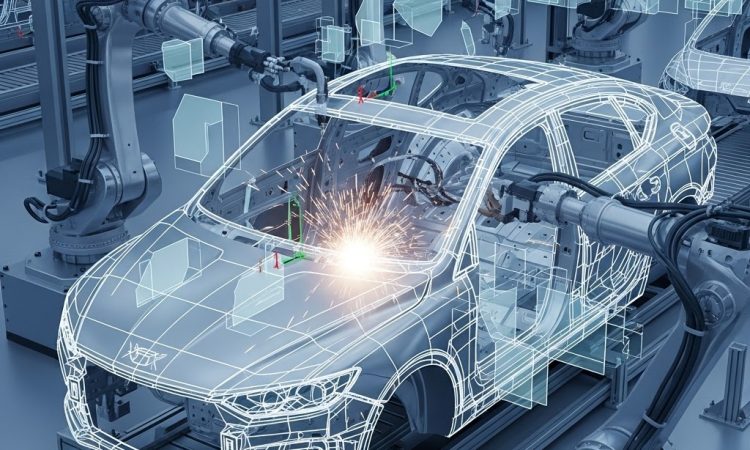

Features:

- Distortion-Aware Simulation

- Virtual Assembly Validation

Features:

- Real-Time Physics Prediction

- Defense-Grade Security

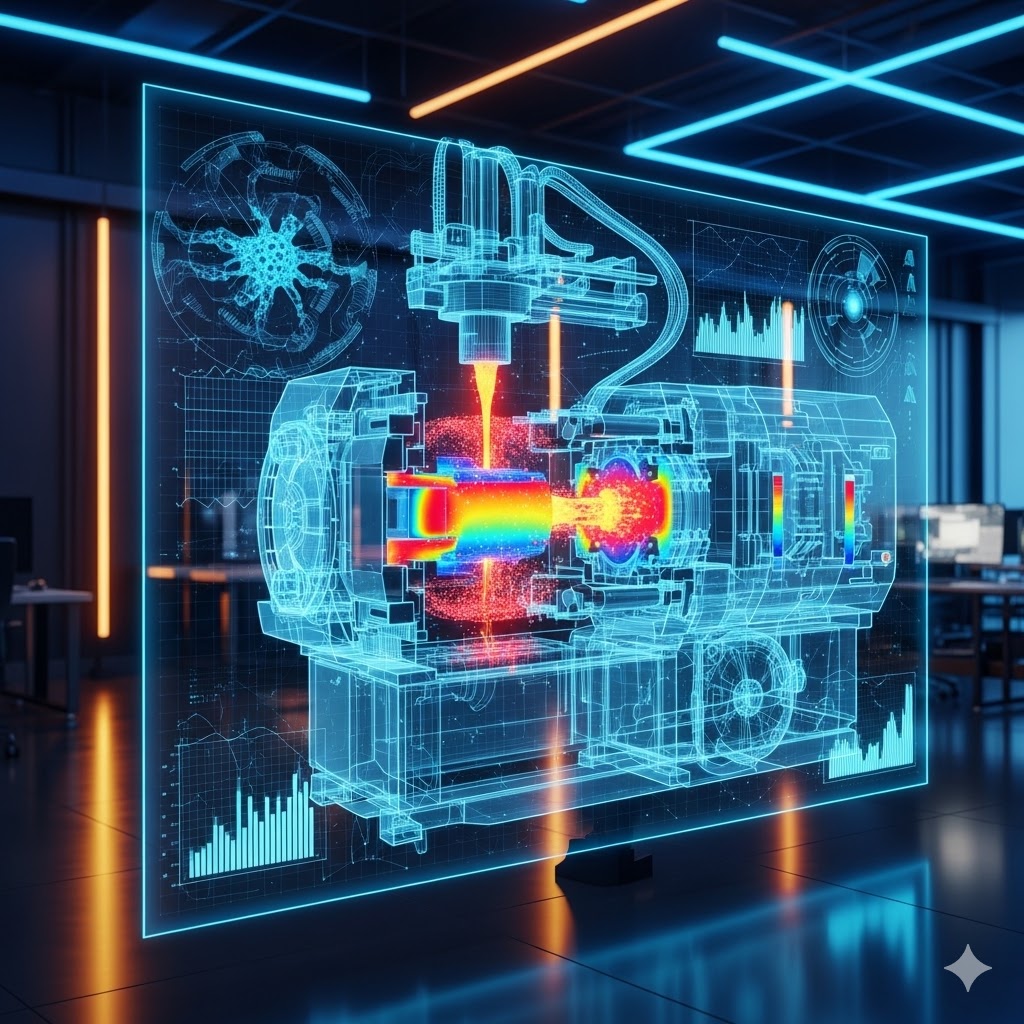

Emmi AI has announced the release of NeuralMould, a Digital Engineer designed to simulate injection molding processes in real time. The model predicts transient melt-flow behavior across different mold geometries and material settings. According to the company, NeuralMould is designed to significantly reduce simulation turnaround times compared with conventional CPU-based approaches. The tool enables more interactive exploration of design iterations and manufacturing parameters, reflecting Emmi AI’s broader push to integrate AI into industrial engineering workflows.

As security systems demand higher image clarity across diverse lighting conditions, simulation is becoming central to optical design. In a blog by Ansys, Emily Gerken explains how engineering teams are leveraging tools such as Zemax OpticStudio and Speos to model light behavior, evaluate lens configurations, and refine performance before physical prototyping. The approach supports faster design validation while addressing the growing complexity of modern surveillance optics. The blog also highlights how companies like KEENFINITY integrate optical simulation into their design workflow to refine imaging performance and address specific needs such as low-light conditions.

Click for original article..

NVIDIA and Dassault Systèmes have announced a long-term strategic partnership to build a shared industrial AI platform, as industrial AI moves from concept toward broader deployment. The collaboration brings together Dassault Systèmes’ Virtual Twin technologies with NVIDIA’s AI infrastructure, open models, and accelerated software libraries. It aims to support mission-critical applications across engineering, manufacturing, biology, and materials science through science-validated World Models and AI-powered virtual companions.

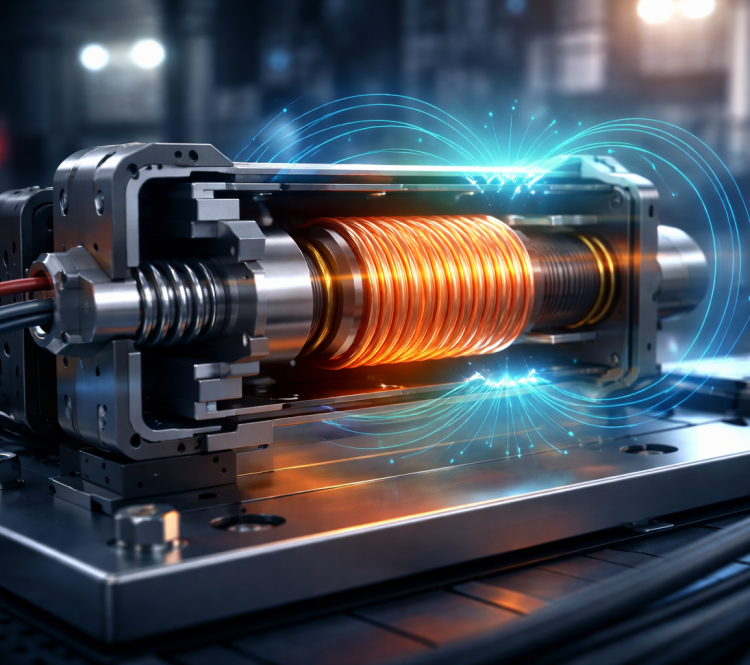

A solenoid turns electrical energy into mechanical motion. From industrial actuators to automotive systems, solenoids’ performance depends on precise electromagnetic behavior. In its blog, SimScale outlines how cloud-based multiphysics simulation can help engineers analyze magnetic fields, coil characteristics, and thermal effects during the design phase. By virtually testing geometry, materials, and operating conditions, teams can better understand performance trade-offs and refine designs before moving to physical prototyping.

Industry Events

This session explores AI-driven concept engineering in battery development, focusing on visualizing cross-domain impact chains, enabling real-time concept evaluation, automating solution generation, and supporting quantified trade-off and change management decisions across electrical, mechanical, thermal, and cost dimensions.

📅 February 23, 2026

🕚 04:30 p.m. IST

This webinar explores how simulation-driven engineering is being applied to improve data center cooling performance. Attendees will learn the integration of AI-enabled workflows, cloud-native simulation platforms, and data-centric analysis to evaluate airflow, heat transfer, and system efficiency. The session aims to address faster design validation while ensuring energy efficiency and thermal reliability.

📅 February 26, 2026

🕣 4:00 p.m. CET / 10:00 a.m. ET

This session explores how certification by analysis builds credible model-based evidence for regulatory evaluation.

Attendees will learn:

- Role of verification, validation & uncertainty quantification (VVUQ) in establishing trust

- Distinctions between verification vs. validation and extrapolation risks

- Importance of software qualification, data governance, and tool credibility

- Engineering judgment when reducing physical tests

- Limitations in VVUQ and emerging AI/ML model considerations

📅 February 26, 2026

🕘 11 AM EST

The event brings together engineers, researchers, and industry professionals to explore the latest advancements in multiphysics simulation using COMSOL Multiphysics®. Through step-by-step demonstrations and technical sessions, attendees are expected to gain insight into core simulation workflows, recent software capabilities and how these tools address challenges in chemical, fluid, structural and electromagnetics simulations. The event aims to serve as a platform to share learnings and broaden understanding of multiphysics approaches.

📅 February 27, 2026 🕤 9:30 a.m.–4:45 p.m. IST

📍Hyatt Centric Ballygunge Kolkata

17 Garcha 1st Lane, Dover Terrace, Ballygunge

Kolkata, West Bengal 700019

In FOCUS

Company in Focus

Who they are

Violet Labs is a San Francisco-based enterprise software company founded in 2021 by a team of industry veterans. The leadership, including CEO Lucy Hoag and CTO Mike Marmar, draws from deep experience at world-class hardware organizations like SpaceX, Amazon (Project Kuiper), Google, and NASA. This unique background—defined by “building cutting-edge products out of both atoms and bits”—led them to create the software solutions they wished they had while managing some of the world’s most complex engineering projects.

Solutions & Technology

The core of Violet Labs’ technology is a cloud-based, no-code integration platform that serves as a central “control plane” for engineering data. Key technical features include:

Math-Aware Requirements: Unlike static documents, requirements in Violet are live-linked to engineering variables and parameters.

- No-Code Connectors: Pre-built integrations that bridge the gap between Mechanical CAD (SolidWorks), Electrical CAD (Altium), and Project Management (Jira/Asana).

- Native Scripting: The ability to run Python, Julia, or MATLAB scripts directly within the platform, interconnected with live project data.

- Automated V&V: Continuous Verification and Validation (V&V) that automatically flags when a design change violates a safety or performance requirement.

Applications:

Violet Labs is specifically designed for multidisciplinary teams building sophisticated hardware. Common applications include:

Aerospace & Satellite Constellations: Managing complex mass and power budgets across thousands of components.

Autonomous Systems: Coordinating the integration of sensor hardware, structural frames, and embedded software for robotics and self-driving vehicles.

Climate & Energy Tech: Streamlining the development of nuclear energy hardware and complex grid systems.

Government & Defense: Utilizing the “VioletGov” version of the platform to meet strict ITAR and EAR regulatory compliance standards.

Did you know?

High-stakes hardware teams often spend nearly a third of their work week manually moving data between different software programs. Violet Labs was built specifically to reclaim this lost time, automating the ‘orchestration’ of engineering data so that a change in a single bolt or circuit board is reflected across the entire project instantly. ”

Solution Focus

The primary focus of Violet Labs is to eliminate the “data silos” that plague hardware development. Traditionally, engineers spend a massive portion of their time manually moving data between different tools, leading to version control errors and delays. Violet Labs shifts this focus toward a “Digital Thread,” where every change is synchronized across the entire tech stack. By providing a single source of truth, the platform allows engineers to focus on high-value innovation rather than administrative data entry, significantly reducing development cycles and engineering overhead.

Technology Focus

Cement manufacturing involves complex thermal and fluid flow processes that directly impact production efficiency, equipment longevity, and emissions control. Air and gas streams move continuously through kilns, preheaters, coolers, ducts, and pollution control systems, carrying fine particulate matter at high temperatures and velocities. Understanding how these flows behave inside large-scale industrial systems is challenging without advanced analytical tools. This is where Computational Fluid Dynamics (CFD) becomes essential. The blog by Wendy Beale and Kevin Linfield, highlights how CFD provides detailed insight into internal plant dynamics, allowing engineers to visualize and optimize processes that are otherwise difficult to measure directly.

Key areas where CFD delivers value in cement plants include:

Airflow diagnostics: Identifying turbulence, uneven velocity profiles, and pressure losses that reduce operational efficiency.

Fan and duct optimization: Improving equipment geometry to lower energy consumption and enhance flow distribution.

Particle tracking: Modeling dust and material transport to minimize buildup, imbalance, and operational disruptions.

Erosion prediction: Locating regions exposed to high particle impact to reduce premature wear and maintenance costs.

- Pollution control evaluation: Assessing the performance of cyclones, baghouses, and electrostatic precipitators for improved particulate capture.

- Emission dispersion modeling: Simulating stack discharge behavior to better understand environmental impact and regulatory compliance.

As outlined by Airflow Sciences Corporation (ASC), CFD allows cement producers to test design modifications in a virtual environment before implementing physical changes. This analytical approach reduces reliance on trial-and-error adjustments while supporting more efficient, reliable, and environmentally responsible plant operations.