Industry News

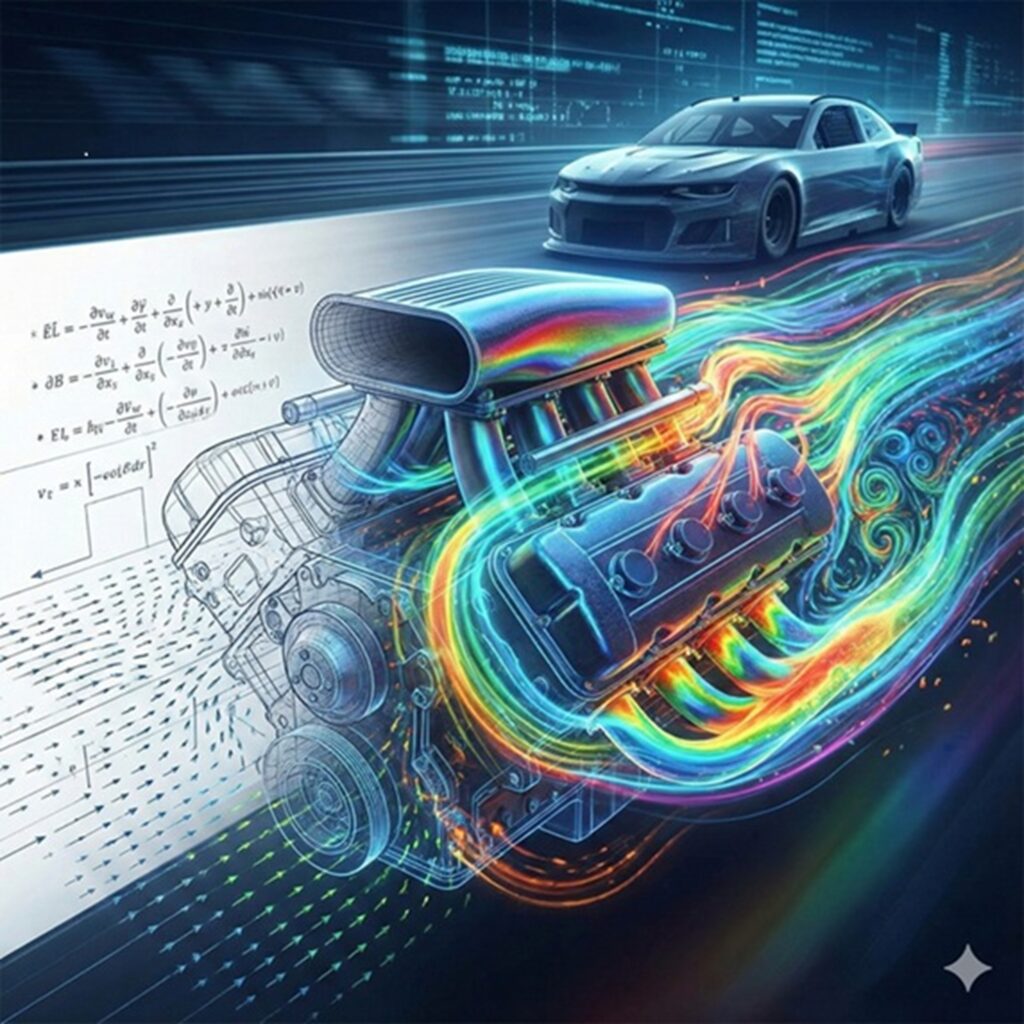

Designing a race engine means pushing performance while keeping the system reliable under demanding track conditions. Racing rules allow only small changes in design each year, so every improvement counts. Roush Yates Engines, the exclusive Ford engine builder for major racing series, uses CONVERGE CFD to evaluate and refine powertrain components during their 8–12 month development cycle. With CONVERGE, they simulate intake manifolds, cylinder head ports, exhaust and intake systems, and cooling behavior to support decisions that help deliver power within tight engineering limits.

Product News

JuliaHub and Synopsys have announced a partnership that combines JuliaHub’s Dyad simulation platform with Ansys TwinAI™. The integration connects AI-based, physics-informed modeling with digital twin workflows, supporting new approaches to hardware design and system optimization. Click for the original article

Keysight Technologies has released Quantum System Analysis, a new EDA tool that allows quantum engineers to simulate and optimize quantum systems at the system level. The release expands Keysight’s Quantum EDA portfolio, which includes Quantum Layout, QuantumPro EM, and Quantum Circuit Simulation. Click for the original article

The model demonstrates the capabilities of Luminary Cloud’s Physics AI platform, which unifies GPU-native simulation, large-scale dataset generation, and model training into a single “Physics AI Factory. Click for the original article

By combining digital twins, 3D visualization, simulation, and factory data, the platform gives engineers a single virtual space to design, test, and refine entire production environments. Click for the original article

Industry Events

Ansys will showcase how robotics systems combine electromagnetic, mechanical, and thermal design using system-level simulations that capture real interactions.

📅 December 16, 2025 🕚 11:00 AM EST

The webinar will demonstrate how to use the Particle Tracing Module to simulate the motion of ions/electrons in semiconductor-processing steps (like etching), helping optimize etching profiles, sputtering effects, and particle trajectories

📅 December 16, 2025

🕚 18:30 IST

The webinar shows how simulation can be used to model brake systems across all powertrains — covering thermal behavior, braking performance, wear, and non-exhaust emissions.

📅 Thu, Dec 11, 2025

🕘 09:00 AM CET / 02:30 PM IST

The webinar shows how engineers can simulate water-network performance — flow, pressure, pump behavior, and system optimization — to design efficient irrigation systems for golf courses.

Available on demand

Duration: 45 minutes

In FOCUS

Company in Focus

Who they are

Emmi AI is a technology company founded in 2024 in Linz, Austria, by Johannes Brandstetter, Dennis Just, and Miks Mikelsons. The team brings experience in physics-driven AI, research engineering, and product operations, including prior roles at CERN and Microsoft Research.

Solutions & Technology

Emmi AI develops AI-based tools that support physics simulation and digital-twin workflows in industrial engineering. Their technology combines data-driven learning with physical modeling to help automate and scale simulation processes.

Their solutions include:

AB-UPT — neural surrogate model for CFD, supporting volume and surface flow predictions

Tools for thermal and multiphysics modelling

Geometry-aware inference, including direct support for CAD-based workflows

APIs for integration into existing simulation environments

Applications:

Aerodynamics for aerospace and automotive

Semiconductor manufacturing processes

Energy systems and thermal equipment

Industrial digital twins at system scale

Did you know?

AB-UPT has been evaluated on public CFD datasets and demonstrated results suitable for industrial-scale aerodynamic modelling.

Solution Focus

Emmi AI is focused on enabling simulation models to operate as part of digital-twin environments — continuously updating with system data and supporting engineering decisions throughout product and system lifecycles.

Technology Focus

Aging rail networks are being pushed to handle higher demand and stricter safety expectations. Instead of rebuilding everything from the ground up, Bentley’s digital-twin vision uses the iTwin Platform to create a continuously updated virtual model of existing rail assets.

With a digital twin, operators can:

Consolidate sensor data, inspection records, and maintenance history into a single view

Monitor asset health in real time, from tracks to signaling systems

Detect issues early and plan maintenance before failures disrupt service

Simulate upgrades and test changes virtually before committing to physical work

In regions like the Middle East, this becomes even more valuable. Rail systems there face extreme heat, sand intrusion, and environmental stress, which speed up deterioration. By weaving climate data and AI-driven predictions into the digital twin, maintenance shifts from reactive fixes to smarter, condition-based planning, helping reduce downtime and extend asset life.

Ultimately, the vision is modernization without waste — new technology working with old infrastructure. Digital twins offer a clearer understanding of the network as it is today, while guiding upgrades and sustainability for the future. For more details, you can read the full story at the link provided.