Understanding CFD-DEM: An Overview

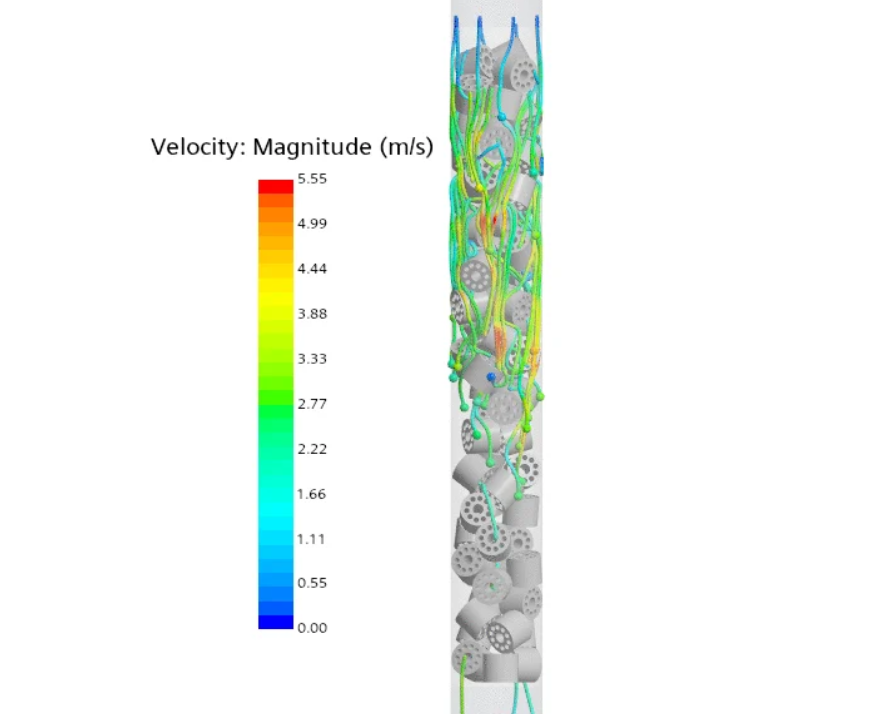

Computational Fluid Dynamics (CFD) and Discrete Element Method (DEM) are two powerful numerical techniques that, when combined, provide an unparalleled tool for analysing and optimizing particle-fluid interactions in various engineering applications. CFD focuses on the behaviour of fluid flow, allowing engineers to simulate and visualize complex fluid dynamics around particles within a system. While DEM, on the other hand, models the actual shape & size of discrete particles (here catalyst particles), accounting for their interactions, collisions and particle packing.

Packed bed reactors are widely used in chemical engineering for processes such as reforming, catalytic cracking, hydrogenation and gas absorption. In these reactors, when tube to particle diameter ratio is lower (<10), the heterogenous nature of packed bed has an impact on the fluid flow and the efficiency of reactions. The size & shape of catalyst particles has significant impact on the economics and efficiency of operation of packed bed reactors. Any real experiments? Well capturing the details of heterogenous packed bed and measuring its performance is experimentally challenging.