When I was a young girl, Valentine’s Day didn’t arrive with a roar; it was a quiet affair. There was not much ado about it—no massive billboards or digital countdowns. Fast forward to a few years ago, and the signals became unmistakable. You knew the day was “round the corner” when local florists overflowed with red roses, street vendors appeared with heart-shaped balloons, and the TV wouldn’t stop shouting about chocolate ads.

Recently, however, I noticed the celebration of the heart had moved from the sidewalk into the script. I saw two different posts from MathWorks: in one, a developer had coded a perfectly layered red rose; in another, a separate script generated a mathematically precise heart.

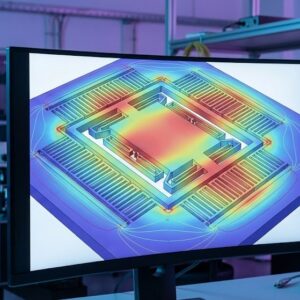

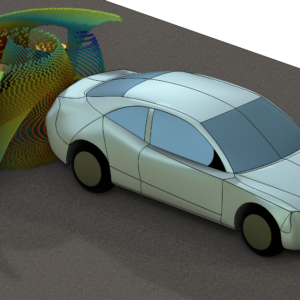

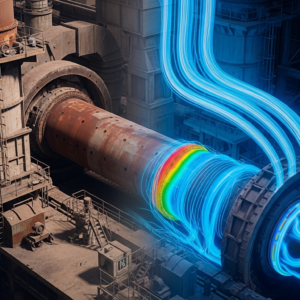

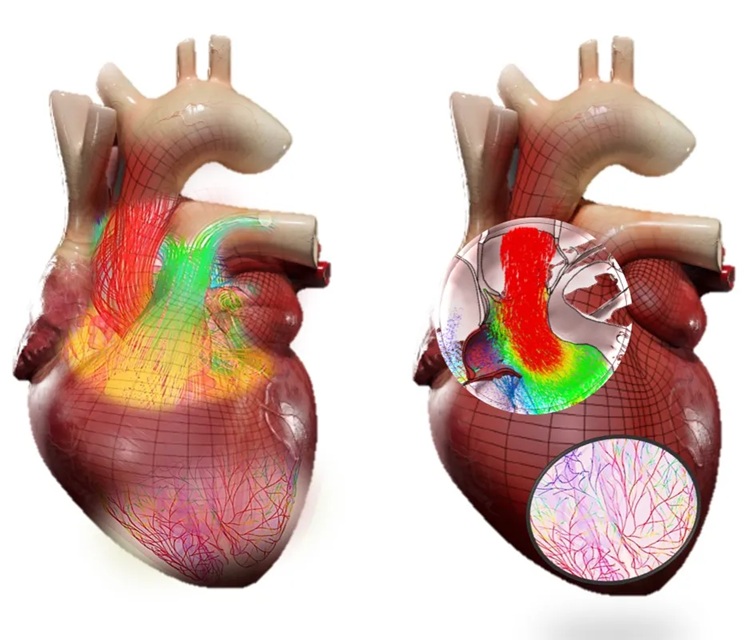

It was a striking reminder of how far technology has come. Having spent 25 years in the simulation industry, I have watched this field evolve from simple structural models to the breathtaking complexity we see today. It struck me that these lines of code represent something far deeper than digital art. The same logic used to render a rose, the ability to turn complex biological forms into mathematical equations—is now being used to save lives.

While a coded rose is a beautiful gesture, an “engineered heart” is a miracle of survival. Today, simulation is the invisible hand ensuring that hearts—from the smallest infants to those needing mechanical help—keep beating!

Virtual Surgery of Smallest Patients!

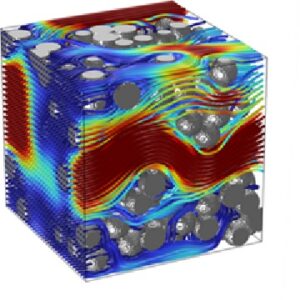

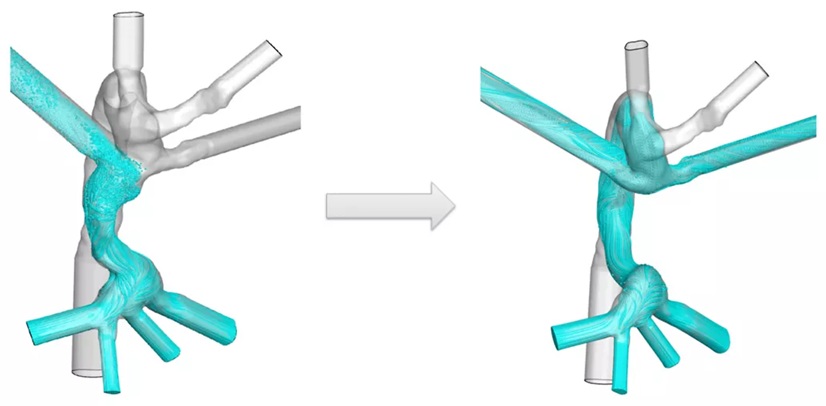

For children born with complex Congenital Heart Disease (CHD), the anatomy is as unique as a fingerprint. At Boston Children’s Hospital, the “Heart Center” has institutionalized a workflow where engineers and surgeons sit side-by-side to “test-drive” surgeries using CFD and structural modeling.

The Innovation: Engineers create patient-specific 4D models from MRI/CT scans to predict how blood will flow through a planned repair. This has matured into Automated Patch Planning, where the AI simulates the ideal patch shape and utilizes a laser-projection system directly in the OR to guide the surgeon’s cuts with sub-millimeter precision.

The Clinical Reach: The program now extends beyond the heart itself into ECMO (Life-Support) Simulation. By modeling the “shear stress” and flow within external circuits, engineers can predict clotting risks, allowing the clinical team to tune life-support configurations to a child’s unique vascular resistance.

The Impact: This predictive approach has fundamentally transformed surgical culture. By treating simulation as a mainstay of clinical care, surgeons can refine their anatomical strategies based on fluid physics, ensuring that high-end engineering serves as a critical safety layer for the world’s most vulnerable patients.

The Evolution of the Digital Twin (MEDITWIN)

The Living Heart Project by Dassault has transitioned from a collaborative research consortium into the MEDITWIN initiative. This shift marks the move from individual models to a scalable commercial framework that uses AI to accelerate the path to clinical use.

The Innovation: The project now features an “AI-powered pipeline” that automates the creation of virtual twins. By leveraging a decade of validated data, it can now generate thousands of unique, fully parametric virtual patient cohorts in seconds—a process that used to take months of manual engineering.

The Regulatory Impact (The “ENRICHMENT Playbook”): In collaboration with the FDA, the project has developed the ENRICHMENT Playbook. This framework establishes the standard for In-Silico Clinical Trials, allowing companies to use AI-generated virtual patients to supplement—or in some cases replace—traditional clinical data for device approval.

The Outcome: This isn’t just theory; it is currently being used to “enrich” clinical trials for heart valves and stents, identifying potential complications in specific patient demographics (like newborns or the elderly) before they reach human testing.

The Death of the “What-If”

Trading Surgical Tension for Calculated Certainty

The operating room has traditionally been a theater of high-stakes emotion—a place where confidence, tension, and the silent “what-if” collide. For decades, a surgeon’s greatest tool was their ability to manage the fear of the unknown!

Today, simulation is dismantling that fear. By resolving anatomical mysteries in a digital world first, we are replacing “gut-wrenching” surprises with calculated certainty. We are moving toward a future where the only thing the surgeon has to focus on is the patient—because the engineering has already silenced the “what-ifs!!”

The Mechanical Marvels

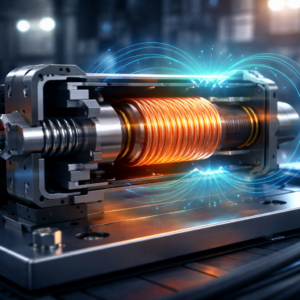

For patients waiting for a transplant, a mechanical heart is a life-sustaining bridge. Engineering simulation is the invisible hand ensuring these devices are both durable and safe for the human body.

The Innovation: Using the PyAnsys-Heart framework and NVIDIA’s AI microservices, engineers can now “auto-generate” pump configurations tailored to a patient’s chest cavity. Companies like BiVACOR have moved beyond simulation to successful human trials, using MAGLEV technology to eliminate mechanical friction entirely.

The Impact: By simulating “shear stress” at a granular level, 2026-era artificial hearts have significantly reduced the risk of blood cell damage (hemolysis). We are no longer just designing “pumps”; we are designing “intelligent responders” that adjust to a patient’s exercise and sleep cycles in real-time.

Predictive Precision at the Bedside

DASI Simulations represents the critical bridge between high-end engineering and the hospital bedside. Their collaboration with Medtronic has turned predictive modeling into a clinical reality at leading institutions like the Cleveland Clinic, moving structural heart repair from a reactive process to a proactive one.

The Innovation: The FDA-cleared PrecisionTAVI™ platform utilizes AI to transform standard CT scans into a dynamic, 4D predictive environment. Medtronic’s contribution is the integration of their specific valve geometries (such as the Evolut™ TAVR platform) into the DASI system. This allows the AI to perform Structural Finite Element Analysis (FEA)—simulating exactly how the metallic frame of a Medtronic valve will interact with a patient’s unique calcium deposits and anatomical structure.

The Impact: Instead of the surgeon “finding out” how a valve fits during the operation, they can now “see” the result beforehand. By providing this AI “digital co-pilot,” DASI and Medtronic help physicians predict and avoid complications like paravalvular leaks or conduction disturbances. This makes high-stakes heart surgery safer, more predictable, and personalized for every patient.

The New Language of Love

As we approach this year’s Valentine’s Day, the “Excitement” about the day has evolved. We still have the roses and the chocolates, but we also have a global community of engineers and veterans of this industry using simulation to ensure those hearts keep beating.

After two and a half decades in this field, I find it heartening that our most powerful technology is being used to protect the very thing we celebrate today: The Human Heart!

Happy Valentine’s Day!